If you are looking for an aluminum foundry that manufactures aluminum sand casting parts and provides precision parts on time and on budget, you’ve come to the right place.

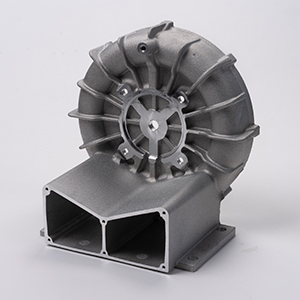

We’ve spent over four decades honing our processes. Perfecting our craft. Expanding our range of capabilities. Managing projects from concept to completion. We do this to stay on the forefront of meeting and exceeding your expectations. Our complex aluminum sand castings move air, water and fluid for some of the largest manufacturers in the country. This dedication has positioned us as a preferred provider as an aluminum sand casting parts manufacturer, and that’s not a responsibility we take lightly.

Let’s work together!

Our highly-successful clientele consists of the following:

While producing high-quality castings is what we do most, it’s not where we stop. We provide a number of final product deliverables to ensure customers receive exactly what they need for their projects.

We utilize the green sand casting method because it is the most versatile approach for producing aluminum products. Virtually any pattern can be pressed into a fine sand mixture to form the mold into which the aluminum is poured. Plus, green sand can withstand extremely high temperatures which provides even more flexibility in producing custom castings.

It all began in 1977 with the construction of an aluminum foundry in Wabash, Indiana by CMI International. Shortly thereafter in 1978, production began. CMI International built the plant to take advantage of the new Corporate Average Fuel Economy (CAFE) regulations. CMI’s strategy was to convert existing and new automotive cast iron transmission, drive train and power train components to lighter weight aluminum alloys to gain market share. They chose a unique Georg Fisher aluminum sand molding process as their vehicle and the Wabash, Indiana community as the driver in this new venture.

Initially, we at the Wabash plant focused on the aluminum green sand casting of high volume engine components like intake manifolds, balance shaft carriers, water pumps and cylinder heads. Later, we added machining and component assembly processes to the plant’s capabilities and floor space.

Over the next four decades, as the automotive aluminum sand casting industry evolved, we successfully evolved with it. As traditional high volume, complex automotive aluminum sand castings were being redesigned into less expensive processes and materials, we successfully developed cost effective solutions for complex, high, medium and low volume aluminum sand cast products that flow air, water and oil for new and emerging automotive and non-automotive market segments.

We have been successful with evolution over the past four decades and it is a testament to the cultural roots established by CMI and to the dedication of the team members at Wabash Castings.

Article from Foundry Management & Technology